Kennesaw State was recognized by the Technology Association of Georgia on Feb. 17 for its cutting-edge, advanced 3D Printing Ecosystem.

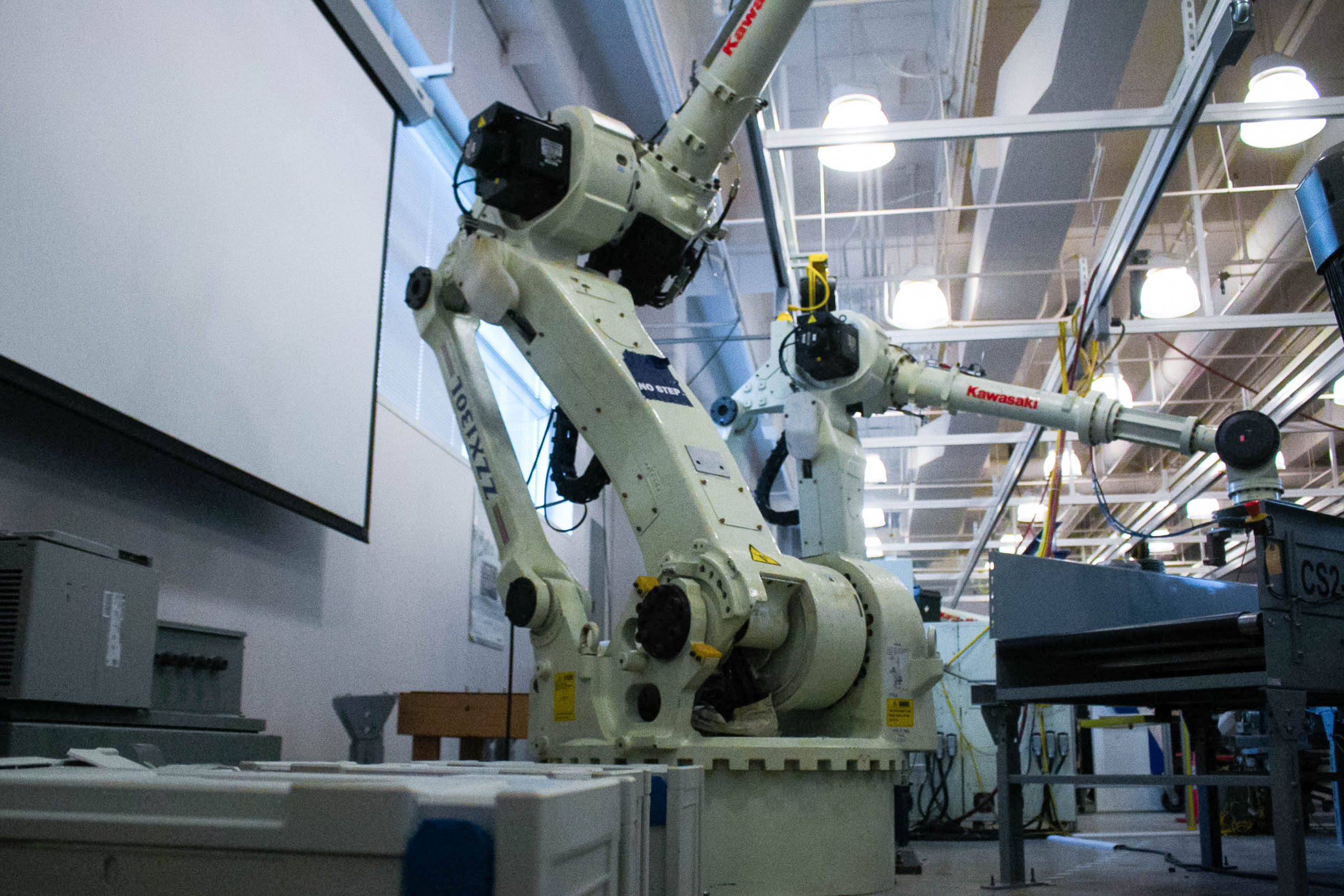

The 3D Printing Ecosystem of KSU is an engineering design system that facilitates 3D printing and scanning, prototyping, manufacturing and collaborating opportunities for students and staff. This intricate web of communication technology allows for students and faculty of both campuses the opportunity to team up and collaborate.

The 3D Printing Ecosystem began as a collaboration between two departments in the Fall of 2020. KSU’s Southern Polytechnic College of Engineering and Engineering Technology and the School of Art and Design partnered to formulate the 3D Printing Ecosystem.

The purpose of this collaboration was to allow art and engineering students to learn from each other. Moreover, this partnership expanded to student major interests beyond arts and engineering.

The KSU 3D printer labs were initially located only in the Engineering and Arts buildings. Since the initial launch of the collaboration, 3D printing labs expanded to the Business, Social Scienceand Architecturebuildings.

KSU’s 3D Printing Center Director and Assistant Professor of Mechanical Engineering, Randy Emert, expressed the unique benefits of this printing ecosystem.

“The 3D Printing software, projects and designs of the five buildings are stored in a cloud-based system,” Emert said.

Essentially, this homogeneous interface allows for students and staff to utilize the singular cloud to interact, network and create with one another.

Moreover, Emert said this ecosystem has over 120 3D printers across both campuses. The large quantity of printers allows for students and staff to integrate this technology into their niche area of studies.

“The ecosystem is about implementing 3D printing into student curriculum,” Emert said. “But, it’s really about the collaboration of different groups of people because this technology brings us all together.”

Art Professor and Collaborator of the 3D Printing Ecosystem, Jeff Campana, clarified why this 3D Printing technology is considered an ecosystem.

“The software and the people are what make this technological advancement an ecosystem,” Campana said. “We have students and staff involved in this process working together daily. We are a team.”

Campana also explained how this 3D Printing Ecosystem at KSU is possible.

“From a monetary standpoint, we were given funds which allowed for the ecosystem to rapidly expand,” Campana said. “We were funded $100,000 to purchase all of the software and technology needed to equip 3D printing labs in the Arts, Business, Architecture, Engineering and Social Science buildings.”

KSU student and 3D Print Lab Student Manager, Allie Benoit, demonstrated the student benefits of utilizing and collaborating with this technological ecosystem.

Benoit said students can use 3D printing technology to transform their concepts and imaginations into tangible, perceivable creations. This 3D printing technology is extremely versatile and appeals to a wide range of students.

“Before I utilized the 3D Printing technology, as a Ceramics Major, I found it more difficult and time-consuming to generate a ceramics piece from scratch,” Benoit said. “This gives me the opportunity to push my ideas further and edit my creations quicker.”

This 3D Printing Technology is also open to every student and staff on both campuses with affordable subscription options.

For more information or to get involved in the 3D Printing Ecosystem, visit KSU’s 3D Center website.